Engineered and solid, the two most common wood types available in the market. Both are suitable for a wide variety of applications, ranging from construction to furniture making, and outdoor projects. Moreover, solid hardwood, including solid wood floors, is a popular choice for flooring due to its durability and natural beauty.

Choosing the right type between engineered wood vs solid wood is crucial for the success of your project and to ensure the final product is up to your expectations. One important factor to consider is the type of finish you want, such as a glossy lacquer or a natural oil finish. Let’s talk about the properties of solid and manufactured wood, their respective pros and cons, and their differences to help you make the right choice for your next woodworking project.

What Is Solid Wood?

Solid wood, also called real wood, is a natural product obtained directly from trees grown in forests and plantations. For generations, timber (trees) has been the primary source of raw material for the construction of furniture, homes, boats, and other things. It is known for its incredible beauty, unmatched natural appearance, and amazing strength. There are two primary types of soild lumber: hardwood, which is obtained from deciduous trees like oak, maple, teak, and mahogany, and softwood, which is obtained from conifer trees like pine, spruce, redwood, and white cedar.

Fully matured trees are felled and cut into boards, which are then used for making furniture and other timber items. There is a wide range of lumber species or types in both hardwood and softwood. Some of the most popular solid lumber species include Teak, Maple, Oak, Pine, Redwood, Mahogany, Cedar, Ash, Beech, Sandalwood, Rosewood, Cherry, and walnut. Each species is different from the others in terms of colour, texture, and other physical properties.

Pros

- Solid wood is prized for its natural beauty and unique grain patterns, which also means that no two surfaces are ever alike.

- Another advantage is its exceptional durability and strength, which ensures the longevity of timber items.

- It exhibits plentiful variety in terms of a diverse range of colours, varying from light to dark brown, and even completely whitish, reddish or blackish tones, depending on the wood species.

Cons

- It’s worth noting that not all species of solid wood are durable and some of them may be prone to damage by moisture and/or insect attack.

- It is also generally costlier than alternatives, primarily due to its limited availability and high demand. The time and labour required in timber production and processing also add to its cost.

- It is generally considered a non-renewable resource, as it can take many years to regrow a forest after harvesting. Therefore, sustainability concerns can be an issue with solid wood harvesting and supply.

To ensure your lumber comes from sustainable sources, you must always buy it from an FSC-certified timber supplier like White Knight Consulting Ltd. t is important to note that the FSC certification ensures that the wood is harvested responsibly and without the contraction of illegal logging practices.

What Is Engineered Wood?

As the number and area of forests continue to diminish, the availability of natural solid wood has also greatly reduced over the years, but the demand for lumber continues to increase. This is one of the reasons why the prices of solid lumber have increased a lot in recent times. Engineered lumber has emerged as a wonderful substitute for the scarce solid lumber.

Engineered or manufactured wood is an alternative that is manufactured in a factory or mill. This is a hybrid material produced by combining wood pieces, particles, fibres, or thin layers (veneers) together using adhesives. Popular examples include Plywood, HDF (high-density fibreboard), particleboard, MDF (medium-density fibreboard), and veneered boards. It can be used in place of real wood for many applications, including furniture making, construction, engineered flooring, and more. Additionally, engineered wood is less susceptible to warping and cracking due to changes in humidity.

Manufactured wood products are often attached with veneers or laminates to enhance their appearance and durability. This makes them easier to maintain and resistant to water.

Pros

- Engineered lumber options are generally more cost-effective than solid lumber, as they are manufactured using wood residue and involve less processing time and cost.

- They are more sustainable compared to solid wood because engineered wood is a renewable resource.

- Engineered lumber offers flexible sizing options, as it can be manufactured in various dimensions and sizes as needed.

- Some engineered wood products such as plywood can be stronger and more durable than many natural lumber species.

- They are also easy to care for, clean and maintain.

Cons

- Manufactured wood generally misses the warmth and natural feel or aesthetic appeal of solid wood.

- They may not last as long as solid wood items.

Engineered lumber comes in many varieties and grades, some of which are very durable and moisture-resistant. Marine ply, for instance, is a waterproof plywood suitable for use in kitchens and bathrooms due to its superior performance in such environments. However, if you’re looking for a more traditional and timeless option, solid wood flooring is a great choice.

Solid Wood vs Engineered Wood

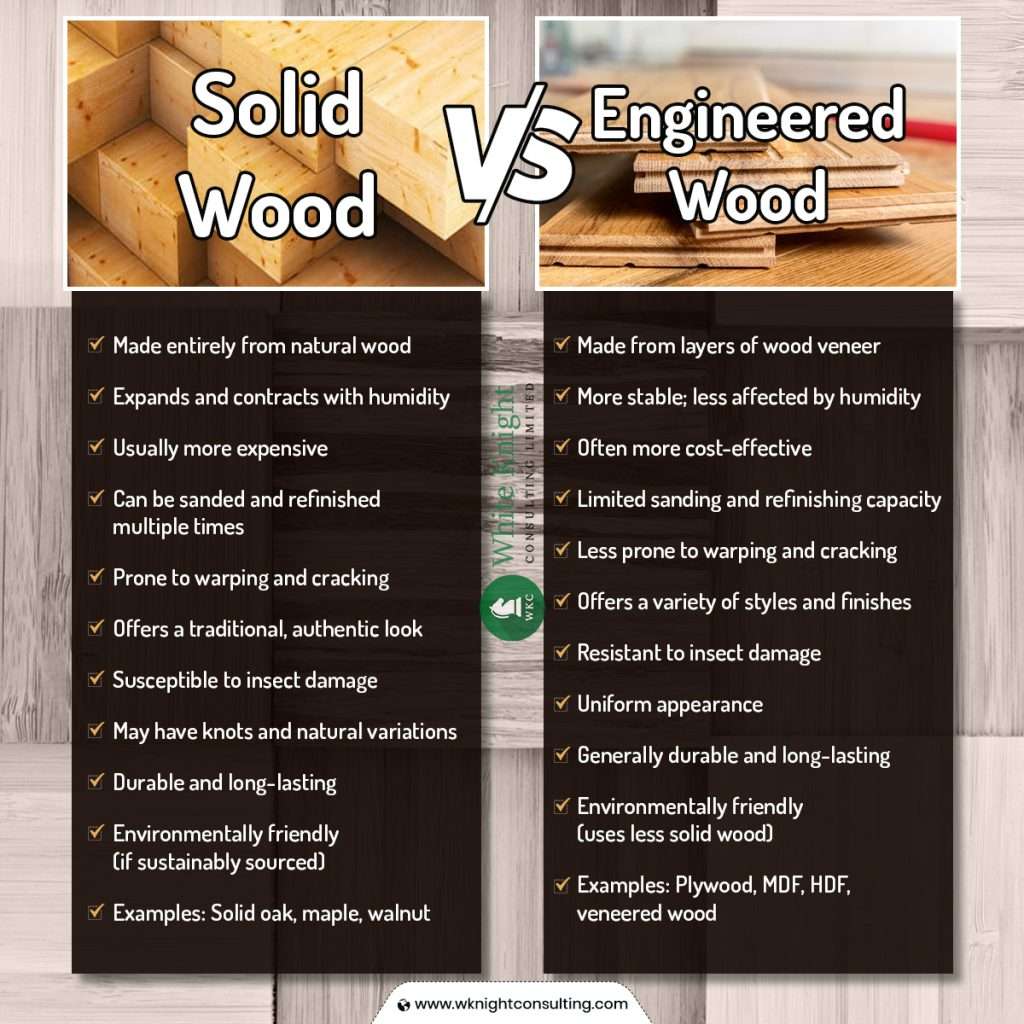

Now that you know all about solid and engineered lumber & their respective pros and cons, let’s sum up the differences between engineered wood vs solid Wood.

Source

Tree logs are felled and cut into slabs or boards of random lengths to obtain commercial solid lumber.

Engineered lumber is manufactured in a factory by combining wood pieces, fibres or veneers with adhesives under specific pressure and temperature to form strong boards with multiple layers of wood. One popular type of engineered lumber is the plank, which is made by bonding together several layers of wood to create a long, narrow board.

Appearance

Solid wood comes in many varieties, offering a diverse array of appearances with colors ranging from light brown or yellowish to darker brownish, reddish, or blackish tones. Additionally, it provides various options for natural texture and grain patterns, enhancing the aesthetic appeal of your items, including conservatories.

Plywood has limited options in terms of appearance. It is good to look at and maintains the natural texture of wood. However, it is possible to enhance the appearance of plywood by attaching a decorative veneer with tongue and groove to the top layer, with plenty of customization options to suit different scenarios.

Types

Solid lumber has two major types – hardwood and softwood – which can further have numerous types or species, such as maple, teak, oak, pine, mahogany, redwood, etc.

Engineered lumber has multiple types based on the core material used to construct it. Common types include plywood, particle board, MDF, HDF, laminated veneer, etc.

Strength & Durability

Solid wood is naturally strong and can be moderate to extremely durable in terms of resistance to decay, rot and insects. Different wood species have different durability characteristics. High-quality wood like teak and oak can last for decades.

Engineered wood’s durability depends on its core material. Plywood is the best type of manufactured lumber in terms of strength, stability and durability. It can be made waterproof using chemicals.

Moisture Resistance

Some species of timber are naturally resistant to moisture, but the same cannot be said for all types of solid wood. Constant exposure to moisture can damage lumber items.

Engineered wood can be made resistant to water by the application of certain methods and/or chemicals. Some plywood types such as marine ply are resistant to moisture.

Hardness

The hardness of natural timber ranges from soft to extremely hard depending on the species. Forest-grown or older trees generally produce harder timber than plantation trees.

Different types of engineered lumber can be medium-hard to very hard. Particle boards, for instance, are really soft, while plywood is very hard and durable.

Workability

Solid wood is generally easy to work with. It cuts well and also holds nails and screws well. It is also easy to paint, glue, and stain. The presence of natural oils or silica can sometimes cause trouble.

Plywood is also easy to work with and holds nails and screws really well. However, particle boards or MDF can result in splintering or cracking when being nailed or screwed because of their soft structure.

Sanding

Solid wood can be sanded an unlimited number of times to return back its shine.

Plywood can be sanded only once or twice. Other low-grade engineered woods cannot be sanded.

Sustainability

Solid wood is not a sustainable or eco-friendly product because growing a forest can take many years or decades.

Engineered lumber is a more sustainable option due to its limited impact on the environment and sustainable production & processing.

Cost & Availability

Real wood is not easily available, particularly popular woods such as teak, oak, maple, mahogany, cherry, etc., and can be very expensive.

Engineered woods are easily and widely available, as they can be manufactured on demand and are generally less expensive.

Engineered Wood Vs Solid Wood : Uses

Solid wood is considered suitable for a huge variety of applications, ranging from furniture making to general construction, flooring, cabinetry, musical instruments, sports equipment, kitchen tools, and decorative items. Moisture-resistant wood can be used in outdoor applications such as decking, boatbuilding, outdoor furniture, etc.

Engineered wood can be used for many purposes, including interior furniture, cabinets, shelves, structural elements for buildings, flooring, doors, windows, packaging materials, boxes, and more.

Where to Buy High-Quality Solid or Engineered Lumber?

If you need help selecting the right lumber for your project or confused between engineered wood vs solid wood, give us a call to consult with an expert at White Knight Consulting Ltd. We sell all kinds of timber species, including 40+ types of hardwoods & softwoods at affordable prices.