OSB (Oriented Strand Board) and CDX are the two most popular engineered wood options for making plywood and other manufactured wood products.

If you’re confused about which one would be better for your next project or how to choose between OSB and CDX, here’s everything you need to know about the two most famous plywood products in the world.

What are OSB and CDX?

OSB and CDX are two popular types of engineered wood.

Engineered wood is a type of manufactured wood product that is made by combining wood particles, fibres, or veneers using adhesives to form a strong and almost waterproof board that looks like real wood but is better and less expensive.

There are many types of engineered wood available in the market, such as plywood, particle board, OSB, CDX, fiberboard, MDF, HDF, etc. Different engineered woods have different properties. Some are more durable than others. Some types of engineered wood are even better than solid wood in terms of physical specifications such as strength and durability, and they are almost always less expensive than real wood.

What is OSB?

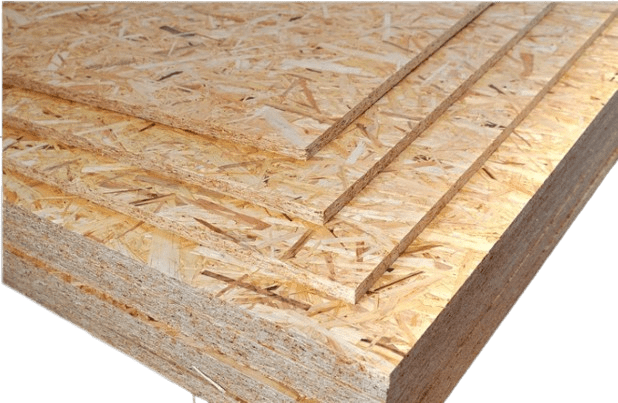

Oriented Strand Board is referred to as OSB. It is a variety of engineered wood board that is frequently employed in building and architecture. Under high pressure and heat, layers of wood fibres are pressed and joined to create OSB.

OSB is famous for its durability, strength, and versatility. Tiny wood particles that are arranged in a certain pattern provide the panel with its strength and stability. To distribute the weights evenly and reduce warping or splitting, the strands are often laminated in layers. Each layer is parallel to the layer underneath it.

- OSB/1: OSB-1 is the most fundamental variety of OSB and is typically applied in non-structural applications.

- OSB/2: Compared to OSB/1, OSB/2 is a versatile structural wood panel that performs better.

- OSB/3: OSB/3 is a construction wood board with good performance that is made for usage in humid situations.

- OSB/4: OSB/4 is the best OSB grade available, offering the best performance and durability.

Advantages of OSB:

- Strong and dense wood

- Less expensive than regular solid woods

- Easily available in large panels/boards

- Suitable for many uses

Disadvantages of OSB:

- Can be difficult to paint

- Difficult to nail and screw

- Takes a long time to dry

What is CDX Plywood?

Plywood of the type CDX is frequently employed in construction and building-related applications. The abbreviation “CDX” stands for “C-D Exposure,” and it denotes the quality and sturdiness of the plywood. For use in outdoor and building applications where contact with moisture and environmental elements is a concern, CDX plywood is preferred over other options.

The front side of the plywood, which is normally a lower grade, is represented by the “C” in CDX. There could be obvious knots, spots, and flaws on the surface. The “D” stands for the back grade, a lower grade that shares many traits with the face grade. The “X” in CDX denotes that the plywood’s layers were joined using glue that can withstand exposure to moisture.

Advantages of CDX:

- Easy to paint and polish

- Cost-effective than solid wood

- Easy to nail and screw

- Suitable for interior work and flooring

Disadvantages of CDX:

- Not available in large panels

- Not durable in terms of water resistance

- More expensive than OSB

OSB vs. CDX : What’s the Difference?

Oriented strand board (OSB) and CDX plywood both have unique qualities that make them appropriate for different purposes.

Durability & Resistance: Due to its low resistance to moisture contact, CDX plywood can be damaged by extended water exposure. The exception is pressure-treated CDX plywood, which can sustain high moisture levels without experiencing water damage. On the other hand, due to the adhesive and resin used in its manufacture, OSB naturally resists water.

When it comes to stability in dimensions, CDX plywood readily absorbs water but also swiftly releases it, resuming its former shape. OSB, on the other hand, is less likely to absorb water, but when it does, it takes more time to dry and return to its previous state.

Cost: OSB is generally more reasonable than CDX plywood in terms of price, making it a better choice. However, lumberyards and shops sell these products easily and at fair prices. Buy wood from reliable & authentic sources such as White Knight Consulting Ltd for the best price and genuine product.

Applications: Subflooring and roof sheathing frequently employ CDX plywood, so long as it is shielded from excessive moisture. To avoid damage, routine maintenance and appropriate covering are crucial. Due to its ability to stand up to moisture, OSB is perfect as a substrate beneath roofing or decking. It functions as nicely for roof sheathing, however in order to stop water absorption, the edges must be coated with a water-resistant material.

The decision between CDX plywood and OSB ultimately comes down to the particular needs of your project and the intended use.

Difference Between OSB and CDX : Summary

| OSB | CDX | |

| Weight | Heavier than CDX | Less heavy |

| Workability | Excess resin can lead to problems when cutting. It does not hold nails and screws well. | Generally very easy to work. Works well with cutters and holds nails and glue well. |

| Availability | Easily available in large panels | Smaller panels commonly available |

| Water-Resistant | Resistant to moisture | Not resistant to moisture. Must be treated before exterior use. |

| Price | Lower than CDS | More expensive than OSB |

Uses | Sheathing, sub-flooring, decking, roof cover, furniture, interior applications | Interior structure, subflooring, walls, decking, roofs |

OSB vs. CDX : How to Choose the Right Engineered Wood

Both OSB (Oriented Strand Board) and CDX plywood are preferred options for a variety of construction and building applications. To help you make the best choice, take into account the following factors:

Moisture Resistance: OSB is typically a superior option if your project calls for materials that can survive exposure to moisture. Due to the production process, it has built-in water resistance, whereas CDX plywood has low durability and may be vulnerable to damage from water if exposed for an extended period of time.

Cost: OSB is a recommended alternative for projects with a tight budget because it is often more affordable than CDX plywood. However, it’s crucial to evaluate the precise needs of your project as well as the durability and long-term advantages of each material.

Application: Think about the precise application you require engineered wood for. When employed as sub-flooring or roof sheathing, CDX plywood can offer good stability and strength. The moisture resilience of OSB makes it a popular base for roofs or decking.

Evaluate the climate and environmental factors that will affect the use of engineered wood. The moisture resistance of OSB may be a considerable advantage if the job involves humid conditions or locations that are prone to moisture.

Accessibility: Lumberyards and retail establishments carry both OSB and CDX wood options in large quantities. Make sure the desired material is easily accessible and fits the project’s requirements.

In the end, the type of plywood you should choose will depend on your project’s exact requirements, budget, moisture exposure, location, and stability requirements. If you’re still not sure, feel free to visit our official website and consult a professional or ask for expert advice.

White Knight Consulting Ltd is a top manufacturer, supplier and global exporter of premium quality hardwood, softwood and a range of wood products. We also provide wood consulting services including expert advice and help in choosing the right wood based on your project. Contact us to know more.